If you spend any time at all with a machinery diagnostic engineer, the first thing you will learn is that they almost never rely solely on vibration data. Instead, they need a full “tool kit” of data. In fact, their first task upon arriving at site to collect data – or to remotely analyze data from an online system – is usually to get supplementary process data. This includes not just measurements on the machine such as bearing temperatures, lube oil pressures, and winding temperatures on motors, but also the process conditions surrounding the machine – suction and discharge pressures, gas composition particulars, flow rates, etc. Basically, anything and everything that will help answer the question: is the process causing the machinery issues or vice-versa? In fact, most machinery engineers will tell you that they are greatly hampered when armed with only vibration data.

Equally important is the role of so-called “process variable” measurements in protecting a machine – not just supplementing its condition monitoring data. Bearing temperatures and motor winding temperatures are perhaps the two most common measurements used for machinery protection purposes, but there are others as well.

The importance of process variable (sometimes called “quasi-static”) measurements is thus well-established and it is vital that a monitoring system possesses the ability to support such signals. In this article, we’ll examine the all-new AMC10MK2 module, part of our VM600MK2 platform1, and some of the reasons why it often makes sense to bring process variables into the monitoring system directly rather than indirectly via the DCS, historian, or other automation platform.

[1] MK1 designates the original VM600 platform and its constituent modules. MK2 designates our second-generation version of the VM600 and its constituent modules. You can learn more about the differences between MK1 and MK2 modules and racks, as well as backwards/forwards compatibility, in the resources at the end of this article or by contacting your nearest vibro-meter representative.

Standards such as API 670 include bearing temperatures in the machinery protection system, measured via RTDs2 or TCs3. Indeed, quite a bit of space in the 670 standard is devoted to mounting and installation considerations for such sensors on both thrust and radial bearings. The standard also peripherally mentions motor winding temperatures, typically assuming two temperature sensors per phase for a total of six per motor on the large, industrial 3-phase units that are commonly used as prime movers. This explains why temperature monitors have historically been 6 channels – so that a single monitor could handle a single motor. Given the prominence of these measurements in API 670, it is no surprise that most users consider bearing temperatures and motor winding temperatures to be a part of the machinery monitoring system – not the process control system.

But aside from temperatures, there can be other measurements that are vital such as suction and discharge pressures on pumps and compressors, not to mention suction and discharge temperatures. Flow rates can also be important along with drum levels, gas composition, and perhaps differential pressures on things like inlet air filters for gas turbines to ascertain clogging / obstructions / debris. In the hydro world, monitoring not just turbine-generators, but also assets like spillway and control gates can be important, too. Monitoring these gates generally entails not just vibration, but temperature, load, gate position, and motor power – all of which are typically process variable type signals (i.e., 4-20mA) rather than dynamic vibration-like signals.

It is thus important for a monitoring system to accept not just temperature inputs directly – without incurring the additional costs and failure points of a “transmitter” to convert the temperature signal into 4-20mA – but to also accommodate true process variable signals that exist in a quasi-static, proportional current format (i.e., 4-20mA).

[2] Resistance Temperature Detectors

[3] Thermocouples

While a protection signal obviously needs to be hardwired directly to the monitoring platform, what about condition monitoring signals?

In some cases, when dozens or hundreds of points must come into the condition monitoring environment, a software interface is the right choice – often based on Modbus, Profibus, OPC, or some other open industrial protocol.

In other cases, however, the process data must be used for making highly accurate decisions about sequence of events and cause/effect relationships, meaning that the incoming data needs a common, accurate timestamp. And, it may be necessary to collect the data relatively fast under certain conditions – such as 5-10 times per second – and this might exceed the scan rates of the PLC or DCS. In still other cases, it might be found that the cost to bring a point in via the DCS or PLC environment is prohibitively expensive. We have had anecdotal reports from customers that hardwiring a process point into their DCS can cost anywhere from 2-5 times more than bringing that same hardwired point into their machinery monitoring system. While this may or may not be typical, cost is certainly always a consideration as well as how fast the data will be scanned when high-resolution trends are required. For all of these reasons, there is often a compelling argument to bring in selected process points directly to the monitoring system rather than indirectly via the DCS and a software interface to import the data.

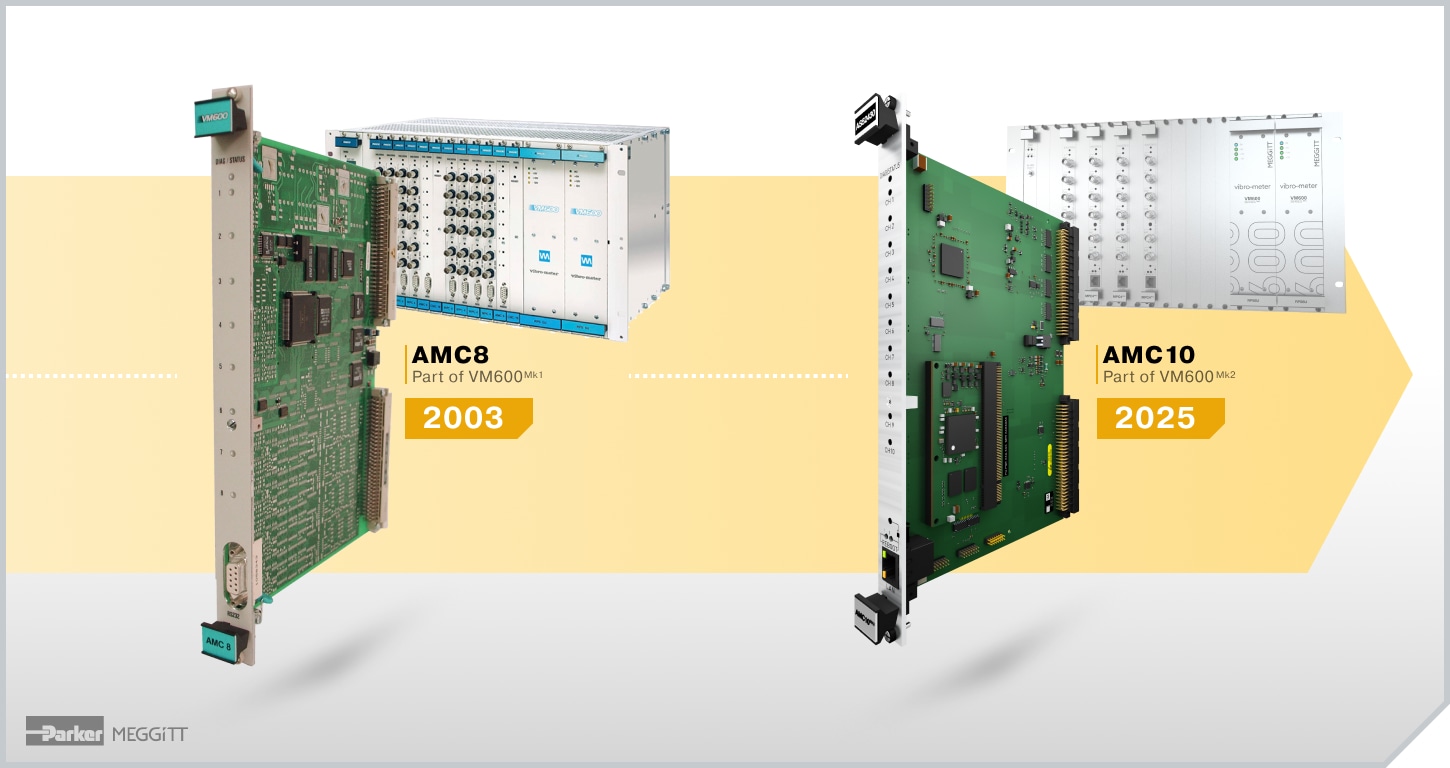

As has been established, the need to bring temperature and process points into the machinery monitoring platform as hardwired signals is often necessary. Our monitoring platforms have thus always supported such capabilities, and the VM600 is no exception. In the first-generation product this was accomplished via the AMC8 (Analog Monitoring Card; 8-channel). With our second-generation VM600MK2 platform, we are pleased to introduce an all-new and improved version of the AMC8 – the AMC10MK2. As is obvious from the name, the first improvement is that the module now accepts 10 channels instead of 8, helping to lower installation and lifecycle costs. However, we have made numerous other improvements as well. Hover over the hotspots in the image below to see these changes and improvements.

[vision id="6"]

The AMC10 ensures that all of the capabilities of the first-generation VM600 now have second-generation counterparts that equal or exceed the capabilities of the prior version4,5. This is true whether talking about the first-generation vibration protection card (MPC4) or the temperature / process variable card (AMC8).

[4] The number of relays has decreased in the AMC10MK2 (two relays) from the AMC8 (four relays). However, additional relays are available via the RLC16MK2 module and multiple RLC16MK2 modules can be used when many discrete outputs are required via relay contacts.

[5] The AMC8 allowed process variable inputs to be either proportional current (4-20mA) or proportional voltage (0-10Vdc) signal formats. At this time, the AMC10MK2 supports only proportional current inputs (4-20mA) for process variables.

One of the biggest areas of improvement in our VM600MK2 system relative to its predecessor is the ability to combine protection and condition monitoring into a single card. The AMC8, as part of our VM600MK1 platform, did not support this and required two modules: the AMC8 for protection and the XMV16 for condition monitoring. The new AMC10MK2 combines this functionality into a single card, simplifying spare parts and configuration along with further lowering your installation and lifecycle costs.

For those with existing VM600MK1 installations relying on the AMC8, there is now a form/fit/function replacement that allows you to upgrade your rack and all of its modules to next-generation functionality, ensuring that not just vibration measurements are available in the MK2 platform, but also process and temperature.

To learn more about the AMC10MK2 as well as the entire VM600MK2 platform and its improvements over the prior-generation VM600 offeringMK1, the following resources are available:

You can also get in touch with your nearest vibro-meter professional to learn more about not just the AMC10MK2, but our entire solution portfolio including monitoring systems, software, sensors, and available service offerings.