Parker Meggitt vibro-meter's comprehensive range of vibration, dynamic pressure, displacement, air-gap and, rotor motion sensors can be integrated with our monitoring system hardware and software, or third-party systems, to deliver complete solutions for monitoring and protecting critical equipment and processes. These sensors are suitable for standard to industrial environments, including hazardous areas and extreme temperatures.

Our sensors and measurement chains are utilized across various industries where the health of rotating machinery, particularly large and critical machines, is a primary concern. Installed on thousands of machines worldwide, they help monitor and protect these vital assets daily. We offer the best solutions for your measurement and monitoring needs to safeguard your investment, enhancing reliability, machine availability, and output.

Today, our products are trusted by OEMs globally and have been qualified and adopted as standard fit components on machinery used in the energy market (power generation, oil & gas and other industrial applications).

| Accelerometers with External Electronics | |

|---|---|

|

The CA series of sensors are high-temperature, piezoelectric-based accelerometers designed for the long-term measurement and monitoring of absolute vibration in the most severe of environments (up to 700°C).

Key features:

Visit this product webpage here. |

| Accelerometers with Integrated Electronics | |

|

The CE and SE series of sensors are piezoelectric-based accelerometers that come with either attached electronics for higher temperature applications (up to 350°C) or integrated electronics for lower temperature applications (up to 120°C) with excellent low-frequency response (down to 0.2 Hz) . These sensors are suitable for the vibration monitoring in steam turbines, smaller hydro units using rolling element bearings and/or speed-reducing gears that require monitoring using accelerometers, compressors, pumps, and fans.

Key features:

Visit this product webpage here. |

| Moving-Coil Velocity Sensors | |

|

Our CV21x and VE210 moving-coil velocity sensors have the advantages of being self-powered and providing a strong output signal in native velocity units (mm/s), so the signal to-noise ratio is excellent, and no integration is required.

Key features:

Visit this product webpage here. |

| Dynamic pressure sensors | |

|

The CP series of dynamic pressure sensors are high-temperature, piezoelectric-based pressure sensors designed for the long-term measurement and monitoring of combustor pulsations and combustion dynamics in gas turbines.

Key features:

Visit this product webpage here. |

| Proximity probes | |

|

The TQ series covers a broad measurement range from 2 to 12 mm and are designed to withstand pressures up to 100 bar from speed and vibration to large-displacement expansion measurement using pendulum probes.

Key features:

Visit this product webpage here. |

| Air-gap sensors | |

|

The LS series of air gap sensors covers a broad measurement range from 5 to 60 mm (linear), features enhanced filtering of noise and spikes and provides outputs for monitoring and protection, including a minimum gap signal for direct protection.

Key features:

Visit this product webpage here. |

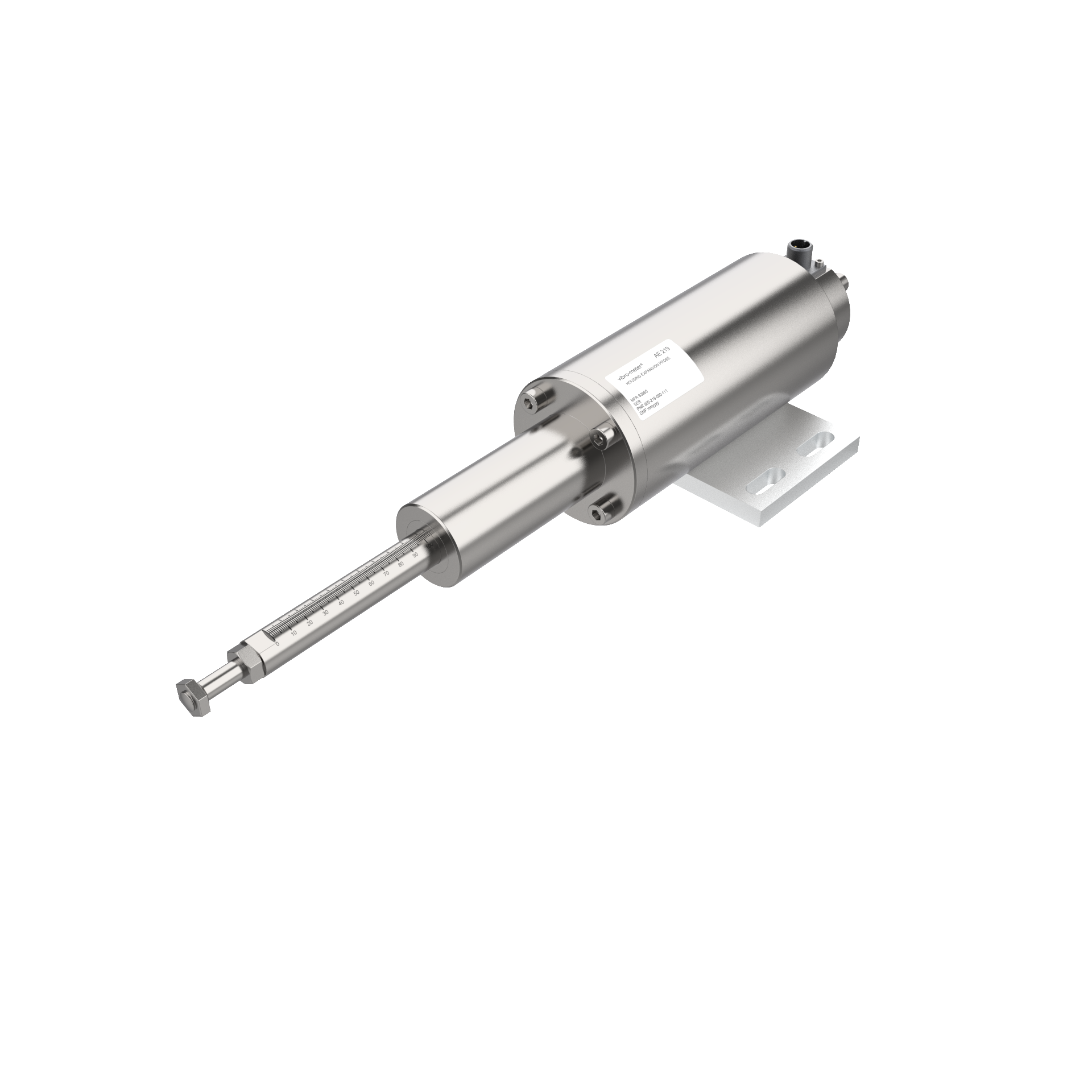

| Housing expansion probes | |

|

The AE219 housing expansion probes use LVDTs for the measurement of casing expansion on the high-pressure end/side of large steam turbines.

Key features:

Visit this product webpage here. |

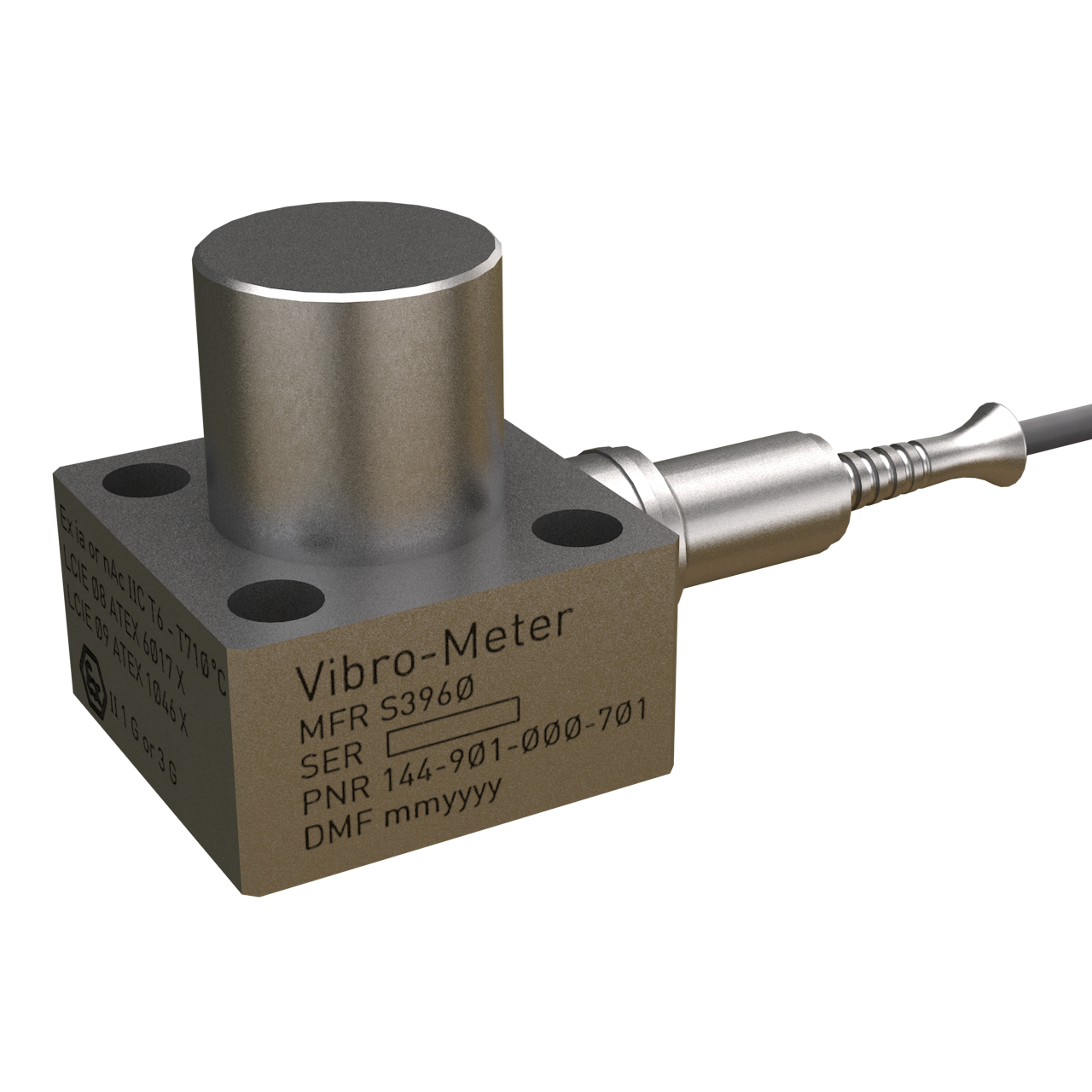

| General-purpose vibration sensors | |

|---|---|

|

Our range of compact and cost-effective piezoelectric velocity sensors enable general-purpose vibration monitoring solutions, for example, PV660 with a voltage output (down to 1.9 Hz (114 rpm)) and PV685 with a 4-20 mA current loop output (down to 3 Hz (180 rpm)).

Visit this product webpage here. |

| General-purpose proximity probe sensor | |

|

The WW and RE series of proximity sensors are used in combination with a transmitter or converter for direct 4 to 20 mA current measurement of shaft vibration or relative displacement. Measurements are made according to the eddy-current principle.

Visit this product webpage here. |